CHALLENGES IN ROAD CONSTRUCTION

The quality of the road plays a major role in economic efficiency, sustainability and driving safety. In addition to increased road durability, premium quality offers significant advantages. These include lower noise pollution, lower fuel consumption, longer vehicle maintenance intervals and greater safety thanks to better grip. This means that all parties benefit equally: Environment, foreman and citizen.

CREATION QUALITY

Quality factors such as optimum smoothness and perfect compaction of asphalt layers are a decisive factor for long-lasting roads and low-noise traffic. This can only be achieved with a precise measurement and control system.

CREATION COSTS

Often asphalt paving is the decisive factor on how profitable a construction project is. The goal is to pave each asphalt layer with just the right amount of material while providing the best possible quality.

PAVING TEMPERATURE

During asphalt paving you can’t measure the temperature without instruments. Paving/compacting at wrong asphalt temperatures leads to bad results.

Solutions

01

THE WORLD’S MOST FLEXIBLE LEVELLING SYSTEM FOR ROAD CONSTRUCTION

MOBA-matic & Big Sonic-Ski

The world-renowned MOBA-matic scores with simple operation, exceptional robustness and absolute precision. Combined with the appropriate CAN-based sensors, even the most complex construction projects can be accomplished.

In more than 45 years on the market, the MOBA control unit and sensors have been perfectly matched to each other to form a single unit.

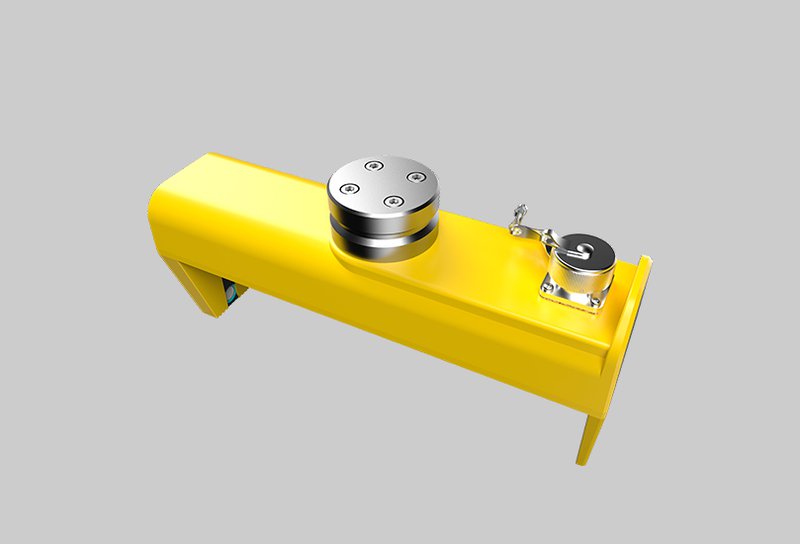

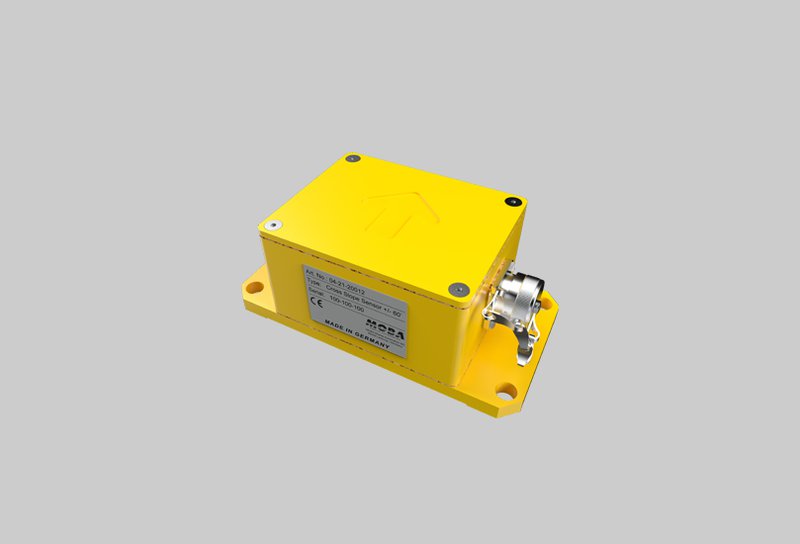

MOBA-matic System components

02

new opportunities for the construction site of the future

PAVE-IR

The quality of the road plays a major role in economic efficiency, sustainability and driving safety. In addition to increased road durability, premium quality offers significant advantages.

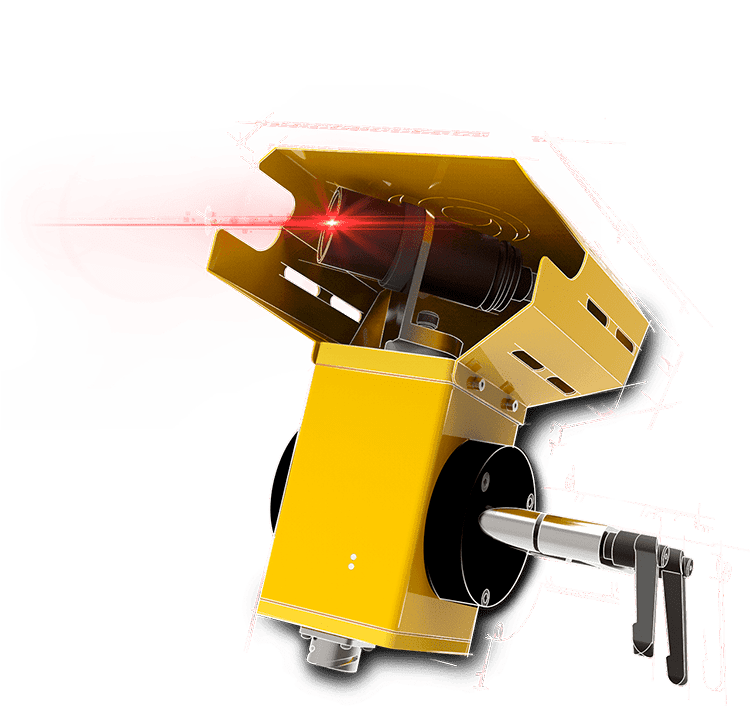

PAVE-IR System Components

03

KEEP TRACK OF LAYER THICKNESS AT ALL TIMES

PAVE-TM System

PAVE-TM, the worldwide first system for the measurement of layer thickness is an absolute must in road construction in order to save costs! After one initial adjustment, the system continuously displays the current thickness of the paving. The system saves you manual re-measuring of the layer thickness and thereby saves time and material. Minimisation of the expensive layer material and exact operation at the tolerance limits reduces your costs to a minimum, thereby increasing your profit.

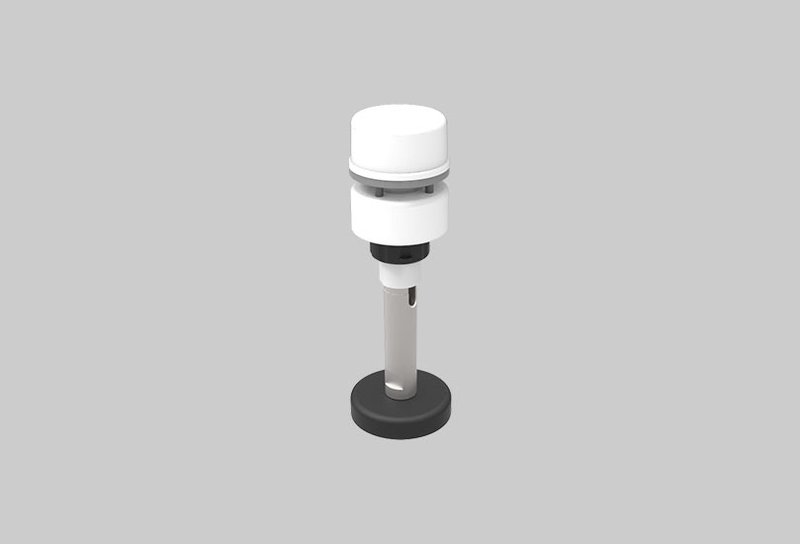

PAVE-TM System Components

04

OPTIMUM COMPACTION IN ASPHALT PAVING and EARTHWORKS

MCA System

With the MOBA MCA add-on system you compact roads and building sites at the highest level every time. Thanks to intelligent temperature, crossing, frequency and amplitude measurement you always achieve the perfect compaction - efficiently and to the point. As a proof of quality all compaction data is also summarized and retrievable from a web server on demand at any time.